Hydro vacuum excavation, also called hydrovac excavation, uses water to remove dirt and other soils. It’s a type of high pressure water jetting that is perfect for excavation services.

It differs from traditional excavation methods in that it is both more efficient and often more environmentally friendly. Land that is removed can be easy put back in place.

What’s more, it minimises risk to underground utilities like telecommunication cables which traditional digging methods can damage.

This blog looks at some of the benefits of hydro excavation and why it might be a good ideas for your next project.

What is Hydro Vacuum Excavation?

Hydro vacuum excavation combines high-pressure water jets with powerful suction to loosen and extract soil or debris around buried services, structures or obstacles.

Instead of employing heavy mechanical digging equipment that can inflict damage or prove disruptive, the hydro vacuum method uses a controlled stream of water to break up material, then vacuums it directly into a containment tank.

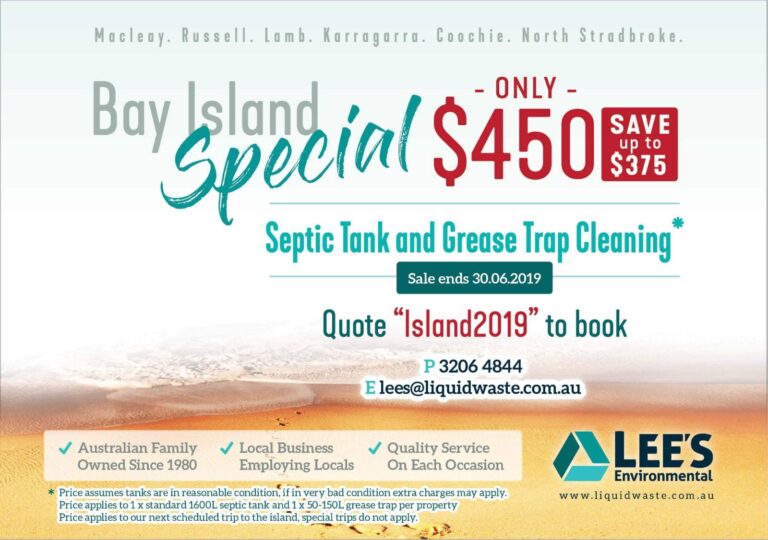

At Lee’s Environmental we offer this service as part of our civil solutions—delivering accurate, safe and efficient excavation without risk to underground assets.

The technique is particularly effective for locating, accessing and exposing services such as stormwater or sewer lines, underground tanks, cable trenches, and other buried infrastructure.

By reducing risk of accidental strikes and by promoting minimal disturbance, hydro vacuum excavation forms a cornerstone of modern service-access strategies.

Reduced Risk to Underground Services with hydrovac services

One of the biggest advantages of hydro vacuum excavation is the significantly reduced risk of damaging underground utilities.

Traditional mechanical excavators can inadvertently hit gas mains, water lines, fibre-optic cables or drainage pipes; the consequences include service outages, safety hazards and costly repairs.

The hydro vacuum process, by contrast, allows for precision excavation around known or unknown services without the large-scale disruption. When a business uses this technique the upside is fewer delays, fewer repair corrections and improved site safety.

Because the method is non-destructive, it is often the preferred option when working near sensitive infrastructure.

It aligns with Lee’s Environmental’s approach to protecting the environment and local communities, ensuring that excavation operations are executed with minimal collateral impact.

Improved Site Efficiency and Access

Hydro vacuum excavation can also deliver faster turnaround times on site. Because the water and suction system can reach confined or awkward spaces, site access is often easier than with bulky mechanical equipment.

On tight urban jobs, beneath paved surfaces or in landscaped zones, hydro vacuum units can operate with less setup, fewer obstructions and smaller footprints.

This efficiency translates into lower disruption for surrounding activity—whether it is a commercial facility, public thoroughfare or operational site.

Lee’s Environmental has found that when a job can be completed more quickly and with fewer resources, the client benefits from reduced downtime and cost savings.

Furthermore the clean-up phase tends to be simpler.

The excavated material is captured in a tank, so there is less need for moving spoil off-site, less spillage risk, and less requirement for restoring surrounding surfaces. That means less labour and reduced reinstatement time.

Enhanced Safety for Personnel and Environment with non destructive digging

Safety is a key consideration on any excavation job. Hydro vacuum excavation offers enhanced safety features over conventional digging.

Because the method does not rely on large mechanical blades cutting into the ground, the risks of contact with electrical conduits, pipework or live cables are lower.

The technique also reduces the chance of cave-ins or soil collapse, as the removal of material is carefully controlled.

On the environmental side, the contained extraction system helps prevent soil and water contamination. With traditional excavation, disturbed soil and debris may migrate, or water ingress may affect nearby services.

Hydro vacuum excavation offers cleaner extraction, capturing the water and excavated material in one controlled process.

Lee’s Environmental utilises modern equipment designed to manage waste streams efficiently, supporting our commitment to environmental stewardship.

Reduced Reinstatement and Landscaping Costs

After excavation comes restoration. With conventional open-dig methods, the surrounding surfaces—paving, concrete, landscaping—often require significant repair or reinstatement.

Because hydro vacuum excavation is minimally invasive, the surface disruption is far less. In many cases the paved surface is unaffected or only minimally disturbed, meaning the reinstatement cost is substantially lower.

From a business viewpoint this means reduced hidden cost. Whether that cost is down-time, restoration works or management of disrupted surfaces, it all adds up.

Lee’s Environmental routinely advises clients that the upfront cost of hydro vacuum excavation often pays dividends in avoiding these downstream restoration expenditures.

Versatility Across Job Types and Industries

Hydro vacuum excavation is extremely adaptable. It works in a broad range of industries—from civil construction to utilities maintenance, municipal works to industrial sites.

Whether exposing cable pits, excavating for patching drains, uncovering tanks, or undertaking clean-outs in congested areas, the method provides a flexible solution.

Lee’s Environmental’s civil services list includes hydro vacuum excavation alongside other offerings such as water-delivery, dust-suppression and jet rodding.

This means we can deliver a coordinated service — a single provider handling multiple site needs — reducing coordination complexity for our clients.

Environmental Benefits of the Hydro excavation process

Businesses increasingly look to minimise their environmental footprint and to choose service providers who share that goal.

Hydro vacuum excavation supports that aim by reducing overall disturbance to soil, minimising spoil generation, and by capturing and managing waste streams more effectively.

These factors align closely with Lee’s Environmental’s broader mission of working efficiently and safely to serve the environment.

By choosing methods that reduce spoil removal, limit damage to existing surfaces and require less rehabilitation, organisations can build sustainability into their excavation strategy. In turn, this contributes to lower carbon-intensity job execution and less waste to landfill.

When Hydro Vacuum Excavation is the Clear Choice

Knowing when to employ hydro vacuum excavation is as important as recognising its benefits.

When the worksite is in a high-traffic area, when underground services need to be exposed with minimal risk, or when surface reinstatement costs must be kept to a minimum, hydro vacuum excavation becomes an ideal solution.

Similarly when a precise excavation is needed around buried assets without major disruption to operations, this method is highly suited.

At Lee’s Environmental we often recommend hydro vacuum excavation in scenarios where standard methods would create excessive disruption or cost.

For example: locating unknown underground services before starting a major build, removing residual material around buried tanks or pipelines, or performing maintenance in sensitive areas like commercial facilities, schools or public grounds.

Integrating Hydro Vacuum Excavation into Your Maintenance Strategy

Integrating hydro vacuum excavation into your site strategy involves considering it not as an optional add-on but as part of the standard toolkit.

First identify high-risk excavation zones—areas close to known services, congested urban sites or locations with complex underground networks.

Then evaluate the likely cost of disruptions, reinstatement and downtime with traditional excavation. Often the offset benefit of hydro vacuum excavation shows up in reduced risk, reduced costs and improved safety.

Lee’s Environmental encourages clients to establish service-provider relationships ahead of emergencies or excavation windows.

When the equipment and team are available on demand, the decision to employ hydro vacuum excavation can be made swiftly, supporting smoother project delivery.

Choosing the Right Service Provider

Selecting a service provider for hydro vacuum excavation is more than just checking off a service list. It involves assessing equipment modernity, operator training, local awareness of underground asset management, and the provider’s environmental protocols.

Lee’s Environmental emphasises its commitment to high-spec fleet, experienced technicians, consistent safety practices and environmental awareness.

Ask potential providers about response times, containment systems, disposal pathways for spoil and water, and the coordination with other onsite trades.

A provider that can deliver hydro vacuum excavation as part of a broader civil or liquid-waste agenda offers extra value.

Lee’s Environmental brings both civil and liquid-waste credentials to the table, meaning our clients gain a single-point partner for varied site-needs.

Summary

Hydro vacuum excavation offers real, measurable benefits for Australian civil and industrial operations: lower risk to utilities, quicker and cleaner access, reduced reinstatement and landscaping costs, improved safety and environmental performance, and adaptable application across industries.

When the job demands precision, minimal disruption and proactive risk-management, this technique stands out.

Incorporating hydro vacuum excavation into your maintenance or construction strategy positions your organisation to handle subterranean works smarter, gentler and more cost-efficiently.

At Lee’s Environmental we bring the experience, equipment and environmental mindset to ensure that when the ground must open, the process is safe, effective and aligned with your business goals.

If you are considering an excavation or access job and want to understand how hydro vacuum excavation can deliver value, contact our team.

We will assess your scenario, recommend the right solution and ensure the works proceed with safety, efficiency and minimal impact.