Blocked stormwater lines, overflowing GPTs (gross pollutant traps), greasy pipework, and sediment heavy culverts don’t just slow operations—they can create safety, environmental, and compliance headaches.

The right jet rodding service partner helps you stay ahead of failures, reduce emergency callouts, and protect assets across industrial sites, councils, and commercial facilities.

In this guide, we’ll walk through 16 practical ways to work effectively with an Australian jet rodding provider, from scoping and safety systems to reporting, waste handling, and ongoing preventative maintenance.

What is jet rodding (and when is it used)?

Jet rodding (often called high pressure water jetting or hydro jetting) uses pressurised water and specialised nozzles to remove blockages, grease, silt, scale, tree roots, and debris from pipes and drains. It’s commonly used for:

- Stormwater and drainage maintenance (pits, pipes, culverts)

- GPT cleaning and pollutant capture support

- Sewer and trade waste lines (including grease heavy systems)

- Industrial cleaning where capture and controlled waste handling are essential

- Emergency unblocking to restore service quickly

Important: high pressure water jetting can be hazardous and is not a DIY activity. Engage trained professionals with the right equipment, safety controls, and insurances.

While similar, it does differ from general hydro digging. If you’re interested in finding out more, I recommend reading this high informative blog from the folks at Enviro-Choice.

Why partnering (not just “calling someone”) saves time and cost with blocked drains

If you only contact a jet rodding provider when something fails, you’re usually paying for urgency, downtime, and avoidable damage. A partnership approach focuses on predictable outcomes, better documentation, and fewer surprises.

- Lower total cost of ownership: fewer repeat blockages and reactive callouts

- Improved asset life: reduced corrosion and wear from chronic build up

- Reduced compliance risk: clearer waste tracking, disposal records, and job evidence

- Faster decision making: CCTV and reports show whether you need repair, relining, or changed maintenance intervals

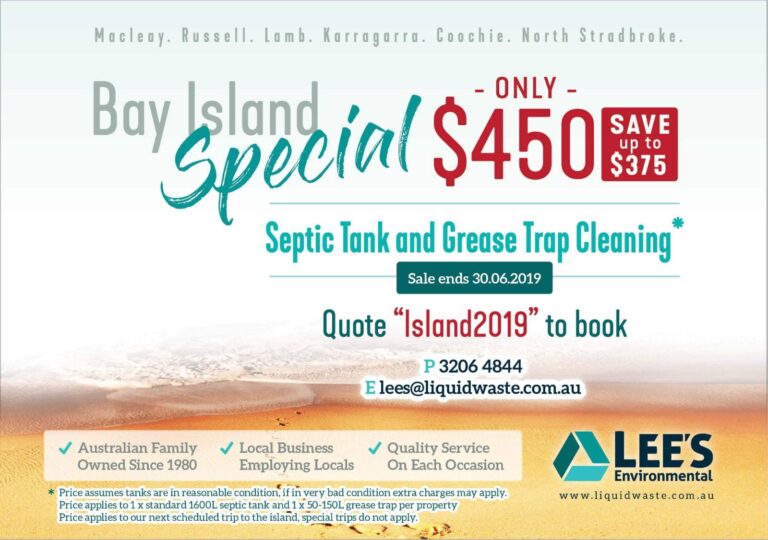

At Lee’s Environmental, we bring a host of experience to how we deal with unblocked drains with jet rodding and other general high pressure cleaning.

16 ways to partner effectively with a jet rodding provider

Now that you’ve chosen to partner with a jet rodding service, it’s vital that you engage in such a way that is both beneficial and long lasting. Below, we explore ways to do so, all of which are drawn from our experience in the industry (and the many successful partnerships we have fostered).

1) Define a clear scope and measurable outcomes

Before requesting pricing, it is essential to define exactly what a successful outcome looks like for your project. Providing a clear scope allows the contractor to allocate the most appropriate crew and equipment for the task.

You should determine whether the primary goal is simply to restore flow, remove specific sediment, or verify the structural condition of the pipework.

Furthermore, consider whether the project requires a rapid emergency response or is part of a planned maintenance schedule, and clarify if the work involves additional services such as CCTV inspections, Gross Pollutant Trap (GPT) cleaning, or culvert maintenance.

2) Confirm local coverage and realistic mobilisation time

Response times are heavily influenced by geography and logistics, so it is vital to confirm a provider’s ability to reliably service your specific location.

Whether your site is in a metropolitan area, a regional hub, or a remote location, you should ask for a realistic estimate of their typical mobilisation times to ensure they can meet your operational requirements.

3) Check licences, site inductions, and safety systems early

For local councils, industrial facilities, rail corridors, and mining operations, strict induction and safety requirements can easily derail a project schedule if not managed early.

You should request evidence of the provider’s Work Health and Safety (WHS) systems and their capacity to complete site specific inductions. It is also important to confirm their high pressure water safety controls and ensure their team can fully comply with your specific permit to work processes.

4) Verify equipment capability (not just “we do jetting and drain rodding”)

Not all jet rodding units are the same, and the ideal setup depends on the pipe diameter, site access, and the nature of the blockage.

You should verify whether the provider uses compact mini reel units for tight access or larger truck mounted units for heavy duty work.

Ensure the pressure and flow rates are suitable for the materials being removed and check that they carry a variety of specialised nozzles for root cutting, descaling, or grease removal.

Finally, consider site constraints such as low clearance car parks, basements, or busy roadways that might require specific vehicle types.

5) Pair jet rodding with CCTV inspection for evidence based maintenance

Combining jet rodding with a CCTV survey provides a transparent, evidence based approach to maintenance.

By conducting a pre jetting inspection, you can identify specific issues like pipe collapses, root ingress, or displaced joints before work begins.

Following up with a post jetting CCTV survey allows you to confirm the effectiveness of the cleaning and document the final condition of the asset, which significantly reduces the likelihood of expensive repeat callouts.

6) Move from reactive callouts to scheduled maintenance of drains and pipes

Transitioning to a planned jet rodding programme is generally far more cost effective than relying on emergency repairs.

Scheduled maintenance reduces the risk of environmental overflows and unplanned operational shutdowns.

You should establish cleaning intervals based on historical blockage data, rainfall patterns, and site usage, ensuring that “repeat offender” lines, pits, and GPTs are prioritised in the schedule.

7) Put environmental and waste handling requirements in the contract

Jetting inevitably generates wastewater and debris that must be managed according to environmental regulations.

Your contract should clearly outline expectations for the capture, transport, and disposal of waste to ensure your site remains compliant.

It is important to define how silt and grit will be contained, where the wastewater will be discharged, and what controls are in place to prevent off site pollution.

Additionally, insist that the provider supplies all necessary disposal dockets and traceability records for your audits.

8) Require proof of insurance appropriate to the worksite

When managing commercial or council assets, it is a prerequisite to verify that the provider holds adequate public liability insurance.

You should also consult with your procurement team to identify any additional insurance categories or specific coverage limits required for your particular worksite or industry.

9) Ask for a written risk assessment and site/traffic management plan

Any works conducted in public facing areas, such as roads or footpaths, require robust site controls to protect pedestrians, motorists, and staff.

You should demand site specific risk assessments and Method Statements (RAMS) or Safe Work Method Statements (SWMS).

Furthermore, ensure the provider can manage traffic control for roadside assets and establish clear exclusion zones to manage the risks associated with high pressure water activities.

10) Agree on emergency response SLAs and escalation paths

For critical infrastructure like main stormwater trunks or high risk trade waste lines, it is vital to define clear Service Level Agreements (SLAs).

Agree upon specific response windows for both urgent and non urgent tasks and establish a formal escalation path.

This should include out of hours contact details and a clear understanding of the communication expectations required while the job is in progress.

11) Align reporting with council or site compliance needs

To ensure consistency across your asset register, reporting requirements should be built directly into the initial scope of work.

Request detailed job sheets that include precise locations, asset IDs, and time stamps.

You should also ensure that any CCTV files are labelled to match your existing records and that all waste disposal evidence, such as dockets and receipts, is provided promptly upon completion.

12) Verify operator training and competency

The hazards of high pressure water jetting require highly trained and competent operators.

You should ask potential partners for evidence of their technicians’ training and regular competency checks.

This includes specific high pressure safety practices, confined space awareness where applicable, and a proven track record of working safely around live services and sensitive operational assets.

13) Use a pilot project to validate performance on complex sites

If you are responsible for a complex network or a sensitive environmental zone, it is wise to begin the partnership with a paid pilot project.

This allows you to test the provider’s capability on a high risk asset or a problematic section of pipe in a controlled manner.

A pilot project provides the opportunity to evaluate their reporting quality and safety standards before you commit to a long term service agreement.

14) Insist on pre and post job documentation (photos, CCTV, and evidence)

Comprehensive documentation is your best defence during audits and is a vital tool for making informed maintenance decisions.

At a minimum, you should require “before and after” photographs of pits and access points, as well as clearly labelled CCTV footage.

Accurate waste tracking and disposal evidence should also be provided whenever material is removed from your site.

15) Integrate results into your asset management system

The data gathered from jet rodding becomes significantly more valuable when it is fed back into your preventative maintenance planning.

By logging dates, locations, and specific findings against your asset IDs, you can track repeat blockages and identify which sections of the network require structural repairs or upgrades.

These condition notes are also essential for justifying future budgets and long term renewal programmes.

16) If you own jetting equipment, prioritise partners with local servicing and parts support

While some organisations use in house equipment for minor tasks, they often outsource more complex work.

If you operate your own gear, it is beneficial to partner with a provider that offers local servicing and spare parts support.

Having access to rapid repairs and essential components can significantly reduce your equipment downtime and maintain your operational readiness.

A quick “partner ready” checklist you can copy into your RFQ

- Scope: asset types, pipe sizes, access constraints, and outcomes (restore flow, remove silt, condition verification)

- Coverage: service area, mobilisation time, and after hours availability

- Safety: SWMS/RAMS, inductions, and high pressure controls

- Equipment: unit type, pressure/flow capability, nozzle range, and capture setup

- Quality assurance: CCTV capability and post clean verification

- Environmental controls: containment, waste handling, and disposal evidence

- Documentation: photos, reports, CCTV files, and asset ID tagging

- Commercials: response SLAs, escalation contacts, and pricing schedule

Where Lee’s Environmental fits: safe, compliant, practical support

If your jet rodding work involves complex waste streams, high risk sites, or you need confidence around safety and documentation, it helps to work with a team that understands compliance and operational constraints.

Lee’s Environmental supports industrial, civil, and council clients with practical, safety led services across the eastern seaboard—including high pressure clean and capture and emergency response capability where incidents escalate beyond routine maintenance. Learn more at Lee’s Environmental.

Next steps

- Want fewer callouts and better reporting? Request a quote or ask about a scheduled maintenance program.

- Need urgent help for an incident? Spill? Call our 24/7 emergency team to contain and remediate—minimising downtime and compliance risk.