Liquid waste management comes in many shapes and sizes, much like other waste management methods. This is in part because a person or company can generate liquid waste in different ways.

But in order to ensure that liquid waste safely ends up where it should, companies who work in the industry, like Lee’s Environment, engage in certain fundamental jobs.

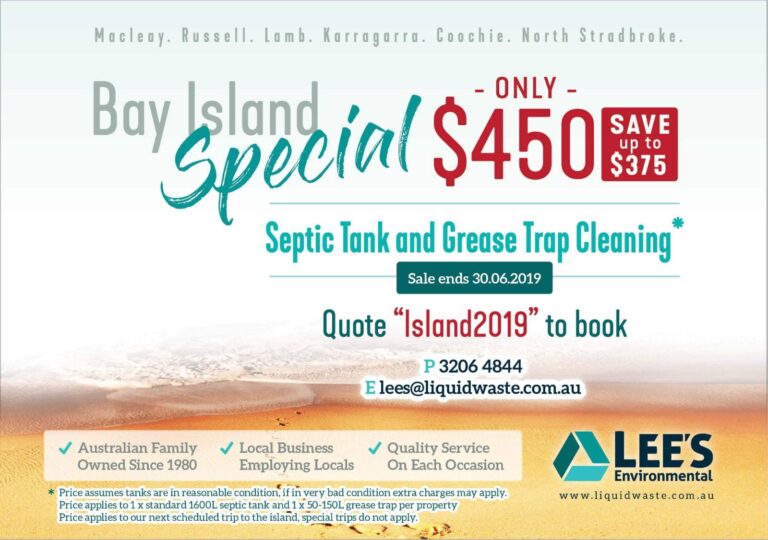

This blog looks at them, from the common services like grease trap waste disposal and septic waste cleaning to the proper disposal and management of industrial wastewater.

Defining Proper liquid waste management

Liquid waste covers a diverse range of materials: wastewater, oily water, storm-water run-off, sludge, contaminated water, holding-tank contents, industrial effluents, sewer or trade-waste pit pumps, and more.

At Lee’s Environmental we list services such as oily-water pump-outs, storm-water and sewer pit cleaning, trade-waste removal and hazardous liquid transport.

Each material presents its own handling and disposal requirements.

A sound liquid-waste programme recognises that varied nature, plans accordingly and executes safe and effective handling.

Managing liquid waste well is more than the removal of visible matter.

It requires drainage management, containment control, flow diversion, pump-out scheduling, sludge removal, system inspection, transport logistics and disposal or treatment of residuals.

In short, a range of ‘jobs’ must be done consistently. Below we detail the major categories that liquid waste services like Lee’s Environmental offers.

Job 1 – Collection, Pump-Out, and Liquid Waste Disposal

Perhaps the most visible task in liquid waste management is the physical removal of accumulated liquids or sludge from tanks, pits, interceptors, capture devices or stand-alone holding systems.

At Lee’s Environmental we operate vacuum tanker trucks and specialised pump-out units for oily water, trade-waste traps and other hold-points.

Efficient collection ensures that the accumulated waste is removed before it becomes a site-problem.

The pump-out job involves locating access points, gaining safe entry where required (especially in confined spaces), connecting hoses, operating the tankers, monitoring extraction volumes, and documenting the service.

Technical know-how is required to ensure that the extraction proceeds safely, without damage to the infrastructure or risk to personnel.

Job 2 – Septic Tank Cleaning, Rinsing and Internal Inspection

Collection alone does not complete the job.

After extraction the tank, pit or separator often requires cleaning and rinsing to remove residual sludge or scum layers that reduce operational capacity.

The internal inspection component is also critical: technician teams check for structural integrity, baffle condition, inlet/outlet performance and signs of damage or mis-connection.

Lee’s Environmental’s services highlight treatment of storm-water/sewer pits, oily-sludge removal, grease trap cleaning and related internal services.

This job ensures that the capture system continues working as designed rather than simply being emptied habitually.

Job 3 – Transport and Disposal of Extracted Waste

Once liquid waste and sludge are removed, the job moves into logistics and disposal: the transporter must deliver extracted material to an appropriate treatment or disposal facility.

This component is essential because the waste may be contaminated, hazardous, or containing oil, chemicals or suspended solids.

At Lee’s Environmental we hold the relevant licences and operate a fleet capable of handling a broad spectrum of liquids, including non-dangerous and dangerous goods.

Effective transport/disposal minimises liability, maximises environmental protection and ensures that the initial removal job is meaningful rather than shifting risk downstream where improper disposal might occur.

Job 4 – Drain and Line Cleaning, Jet Rodding and Blockage Prevention

Liquid waste management often intersects drainage systems, storm-water networks, sewer lines, pits and interceptors.

One fundamental job is the cleaning of these conduits: removal of sludge, silt, grease and roots which impair flow and cause backups or overflow.

Lee’s Environmental lists high-pressure jet rodding and drain cleaning services as part of its liquid-waste offering.

This job is important because even if tanks and pits are regularly cleaned, if lines downstream are blocked the overall system performance will still fail.

Drain and line cleaning assures the waste exits the capture point, the system remains unblocked and the risk of operational interruption is reduced.

Job 5 – Monitoring and Preventive Maintenance

A forward-looking liquid-waste programme includes monitoring of asset condition, waste volumes, sludge-levels, trap performance and servicing intervals in an effort to minimise disposal costs.

This job may be less visible than pump-outs and cleaning, but it is fundamental for maintaining long-term performance.

Businesses that rely on reactive servicing risk higher costs, surprise downtime, odour issues or site disruption.

At Lee’s Environmental, part of the value offered to clients is scheduling of services and tracking of performance across tanks, pits and lines.

Knowing when a collection or cleaning is due, coordinating access and deciding when a deeper inspection is required are all part of this job and helps to protect public health.

Job 6 – Emergency Response and Spill-Support

Liquid-waste management must also accommodate the exceptional: spill incidents, overflows, pipeline breaches, rapid infiltration of storm-water, chemical leaks, or bypass of systems.

This job requires a provider with 24/7 capability and specialised equipment, trained crews and logistical depth.

Lee’s Environmental indicates availability for emergency and spill response in the liquid-waste sphere.

Having the provider ready for the unpredictable is a key element of a comprehensive liquid-waste strategy.

Response must be swift, correct, and integrated with preventive programmes to reduce recurrence.

How These Jobs Fit Together in the Field

When a commercial or industrial business engages a liquid-waste provider, the service they receive is a combination of these fundamental jobs executed in concert.

For example, during a scheduled contract the liquid-waste provider may perform pump-out (Job 1), cleaning and inspection of the tank (Job 2), transport and disposal of extracted waste (Job 3), inspect the lines (Job 4), update service records and schedule the next visit (Job 5), and remain on call for any overflow or blockage incident (Job 6).

From the business perspective the outcome is continuity of system performance, mitigation of environmental risk, reduced downtime and fewer surprises.

Lee’s Environmental promotes this integrated service model across commercial and civil clients.

Why These Jobs Matter for Businesses

Engaging in these tasks ensures that waste-streams generated by your business are handled proactively.

Unattended sludge, blocked lines, overwhelmed pits or unresponsive systems all lead to disruption, cost escalation and potential environmental harm.

While you may focus on your core operations, the liquid-waste system working behind the scenes must be maintained to avoid becoming a hidden liability.

A specialist provider like Lee’s Environmental lets you off-load these tasks to experts, freeing your internal team to focus on value-adding activity while the service-provider ensures liquid-waste tasks are done on time and to standard.

Final Thoughts

Liquid-waste management may sound like a singular service but in reality it comprises a series of interlocking jobs: collection, cleaning, transport, line-cleaning, monitoring and emergency response.

Each of those roles is fundamental to keeping your system working, protecting your site, preserving operational continuity and safeguarding environmental and site assets.

At Lee’s Environmental we deliver across these jobs with purpose-built equipment, trained teams and a service culture built on reliability.

If your business uses liquid-waste systems, or you are reviewing your servicing programme, reach out to us and we’ll walk you through how we handle each job, tailor the schedule and deliver a service aligned with your site-needs.