Oily water waste is a fact of life for many Queensland operations: workshops, wash bays, factories, mines, ports, fuel facilities, and fleet depots.

The challenge is that oily water can quickly move from “operational nuisance” to “environmental incident” if it’s stored, transported, treated, or discharged incorrectly.

If you’re responsible for compliance, safety, or site operations, the right waste partner isn’t just a vendor.

They’re a practical risk control measure that helps you meet Queensland regulations, protect waterways, and keep your business audit ready.

Below are seven steps to help you select an oily water waste management partner in Queensland, with a focus on safe handling, documentation, treatment capability, and long term value.

Why is oily water management needed in Queensland?

Oily water, frequently classified as oily trade waste, is a complex mixture that may contain hydrocarbons, detergents, suspended solids, and various other contaminants.

The mismanagement of these substances carries significant consequences, ranging from pollution events that devastate aquatic ecosystems and affect downstream water users to the triggering of rigorous regulatory action and substantial clean up costs.

Furthermore, improper handling creates immediate on site safety hazards, including noxious odours, slip risks, volatile vapours, and potential fire threats. Beyond safety and legalities, a failure or overflow in wash bays, separators, or sumps can lead to costly disruptions in production.

Step 1: Verify licensing and Queensland oily wastewater regulatory compliance

The primary requirement for any waste management partnership is ensuring the provider is appropriately licensed and operates strictly within the environmental frameworks and regulated waste systems of Queensland.

You must confirm that the provider possesses the legal authority to collect, transport, and deliver oily water waste to approved facilities.

It is essential to understand how they classify oily water and its associated residues, such as separator sludge, as this determines the specific handling and tracking requirements.

You should request a detailed walkthrough of their waste tracking and manifesting process to ensure that records are accurately created, signed off, and stored for future audits.

If your facility discharges treated effluent to a sewer under Queensland Urban Utilities (QUU) or another local utility, you must verify how the provider assists you in meeting your trade waste conditions and pre treatment obligations.

A dependable partner will be able to explain these compliance measures clearly and provide all necessary documentation without delay.

Step 2: Assess real world expertise in oily water waste (not just “general waste”)

Oily water is not a uniform substance; for instance, the waste from a heavy vehicle depot wash bay differs significantly from that of a manufacturing plant’s bunded area.

A competent partner will demonstrate a nuanced understanding of these practical differences by investigating where the waste is generated—whether in pits, bunds, or interceptors—and identifying other present materials such as solvents, coolants, or saltwater.

Expertise is further evidenced by a focus on waste segregation to prevent contamination and reduce disposal costs.

They should also account for site specific constraints, including vacuum tanker access, isolation requirements, and confined space controls.

If a provider offers a quote without asking these fundamental process questions, it should be viewed as a red flag, as effective management must be tailored to the specific site.

Step 3: Confirm treatment and disposal capabilities (end to end, not “we’ll figure it out”)

Since legal and reputational risks are highest at the end of the waste chain, it is vital to choose a partner that can clearly explain the downstream treatment and disposal pathway.

A high quality provider will possess specific expertise in oil water separation, including the ability to manage skimming and the controlled handling of recovered sludge.

They should offer access to laboratory testing to confirm the correct treatment route and ensure that disposal occurs at authorised facilities suitable for the waste’s specific classification.

Furthermore, there should be a transparent approach to residues, ensuring that separated oil and filter media are managed as distinct waste streams with compliant reporting.

When tendering, you should ask where the waste will be taken, how classifications are confirmed, and what protocols are in place if test results reveal unexpected contaminants.

Partners who prioritise recovery and circular economy principles often provide better long term cost stability and ESG outcomes.

Step 4: Evaluate documentation, chain of custody, and audit readiness

You should expect a comprehensive documentation suite, beginning with collection records that detail volumes, waste types, and transporter information.

This must be followed by end to end waste tracking manifests that cover the chain of custody from your site to the licensed facility.

Finally, you require certificates or dockets confirming the treatment or disposal outcome, alongside exception reporting for any deviations such as contamination or access issues.

To stress test a provider’s administrative capabilities, you should ask for a sample documentation pack and enquire about their turnaround times for paperwork, their record storage protocols, and their ability to provide historical data urgently during an audit.

Step 5: Check Queensland industry experience and references

Local experience is invaluable because Queensland sites face unique pressures, including heavy wet season rainfall, high sediment loads, and the strict entry requirements of ports and mine sites.

When reviewing references, look for evidence of the provider managing similar waste and risk profiles, such as heavy vehicle depots or industrial precincts.

A strong reference will highlight the provider’s ability to prevent spills through proactive maintenance and their familiarity with local trade waste approvals and discharge limits.

For example, a capable partner would respond to an interceptor filling quickly during heavy rain by prioritising the job and recommending improvements to stormwater controls, thereby preventing emergency callouts and maintaining clean audit trails.

Step 6: Confirm reliability, maintenance capability, and service standards

Oily water systems rarely fail at convenient times. An overdue separator service or a failing sump pump can lead to immediate overflows and notifiable environmental events.

Reliability should be judged on the availability of scheduled collection options that align with your production cycles rather than relying solely on ad hoc callouts.

A provider should also offer maintenance support for interceptors and pits, ensuring site safe operations through clear traffic management and isolation procedures.

There must be a defined escalation pathway for urgent tasks when volumes spike or weather events occur.

If your oily water management is linked to high risk hydrocarbon handling, it is essential to choose a partner capable of 24/7 emergency spill response to protect your assets and the environment.

Step 7: Compare costs, innovation, and long term value (not just a per litre rate)

While it is tempting to choose a provider based on a simple pump out price, the total cost is heavily influenced by waste composition, testing requirements, and access times.

The cheapest initial quote can quickly become the most expensive if it results in non compliance or operational downtime.

Key cost drivers that should be discussed upfront include the variability of waste composition, the benefits of segregation practices, and the potential for reduced costs through planned servicing rather than reactive responses.

You should also look for a partner who offers innovative improvements, such as suggestions for reducing waste generation or conducting separator performance reviews.

Ultimately, you want a partner who views oily water management as a comprehensive, ongoing program rather than a simple collection service.

A practical shortlist: the “yes/no” checklist for Queensland sites

Use this quick checklist to compare providers consistently across tenders, procurement reviews, or contract renewals.

- Compliance: Can they demonstrate licensing, correct waste classification, and compliant transport and disposal?

- Trade waste awareness: Do they understand QUU (or relevant utility) pre treatment and discharge obligations where applicable?

- Treatment clarity: Can they clearly explain the treatment/disposal pathway and how residues are handled?

- Documentation: Will you receive audit ready records quickly and consistently?

- Site experience: Do they have proven Queensland experience in your industry and site type?

- Reliability: Do they offer scheduled servicing and responsive escalation for abnormal events?

- Long term value: Do they actively reduce risk, improve system performance, and help control total cost over time?

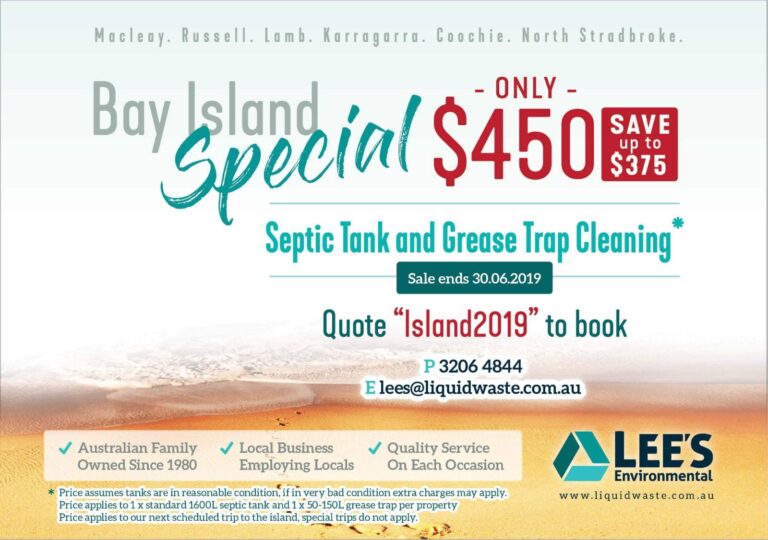

How Lee’s Environmental supports compliant oily water waste outcomes

Lee’s Environmental helps Queensland and east coast businesses solve complex waste problems safely and quickly, with a strong focus on compliance, reliable service, and practical expertise.

If your site generates oily water from wash bays, interceptors, sumps, or industrial cleaning activities, we can help you put a safer, more consistent program in place.

- Hazardous and complex waste expertise: support for correctly classifying and managing regulated waste streams.

- Documentation first approach: traceable records designed for audit and compliance needs.

- Industrial services capability: integrated support that aligns waste collection with site maintenance realities.

- Emergency response: 24/7 spill response when incidents threaten safety, compliance, or operations.

Next step: If you want clarity on your oily water waste stream, storage set up, and collection schedule, request a quote with Lee’s Environmental or ask about a waste audit to identify quick wins for compliance and cost control.