Proper liquid waste management and liquid waste disposal services are difficult to find despite the many companies currently operating across Australia.

Choices are tough because the liquid waste industry is large and you need to be sure that you are partnering with the best possible company.

Additionally, whether you deal with hazardous liquid waste materials, septic waste, septic tank cleaning, or just need a quick liquid waste removal service will change the type of company required.

We’ve put together this blog to help customers find the right liquid waste services for their specific liquid waste management needs.

What is Liquid Waste Management?

The best outline of liquid waste management comes from our blog “Fundamental Jobs in Liquid Waste Management”. Below is a snippet of the definition presented there:

Liquid waste covers a diverse range of materials: wastewater, oily water, storm-water run-off, sludge, contaminated water, holding-tank contents, industrial effluents, sewer or trade-waste pit pumps, and more.

At Lee’s Environmental we list services such as oily-water pump-outs, storm-water and sewer pit cleaning, trade-waste removal and hazardous liquid transport.

Each material presents its own handling and disposal requirements.

A sound liquid-waste programme recognises that varied nature, plans accordingly and executes safe and effective handling.

Managing liquid waste well is more than the removal of visible matter.

It requires drainage management, containment control, flow diversion, pump-out scheduling, sludge removal, system inspection, transport logistics and disposal or treatment of residuals.

Start with your waste streams

Before you evaluate suppliers, map what you generate and how often.

Note that different waste streams require different licences, vehicles and treatment methods.

- Non-hazardous: grease trap waste, septic, wash water, stormwater, interceptor pits, oily water.

- Hazardous: acids and alkalis, solvents, inks and dyes, emulsions, contaminated sludges, hydrocarbons, process chemicals, clinical/liquid biomedical waste.

- By source: food & beverage plants, workshops and wash bays, manufacturing effluent, laboratories, service stations.

Verify licences, compliance and traceability

Compliance is non-negotiable. Ask for proof, and keep it on file.

If they are used to liquid waste management and liquid waste handling, then they will know the environmental regulations and regulatory compliance required.

EPA licences and approvals

- Confirm current EPA licences for collection, transport and treatment in your state(s).

- Check approved facilities and partners used for processing and recycling.

- Cross-check against state EPA resources: EPA Victoria, NSW EPA.

Waste tracking and documentation

- End-to-end chain of custody: consignment notes, digital waste tracking, and certificates of treatment/disposal.

- Audit-ready reporting aligned to your Environmental Management System (EMS).

- Clear waste codes and descriptions for every movement.

Insurances and safety systems

- Public liability, environmental impairment, workers’ compensation — request certificates of currency.

- Documented Safe Work Method Statements (SWMS) and Job Safety Analyses (JSAs).

- Evidence of staff training and fit-for-purpose PPE.

Assess capability and equipment

Capability determines both safety and efficiency, especially on complex or high-volume jobs. In order to handle liquid waste safely, they must have the tools and capacity on hand.

Fleet and specialist plant

- Vacuum tankers sized for your site constraints (tight access vs bulk volumes).

- High-pressure clean-and-capture units for tanks, pits and lines.

- Confined space entry and gas detection equipment where relevant.

Treatment and recycling options

- On-spec treatment pathways for oils, emulsions, acids/alkalis and trade waste — prioritising resource recovery where viable.

- Capability to dewater sludges and reduce disposal volumes.

- Clear stance on circular-economy outcomes (re-refining, beneficial reuse).

Emergency response readiness

- 24/7 spill response coverage, on-call crews and rapid mobilisation.

- Containment, neutralisation and remediation expertise.

- Integration with your incident procedures and reporting.

Check service scope: one partner, fewer headaches

A full-service provider streamlines scheduling, site onboarding and reporting.

- Liquid waste collection and transport.

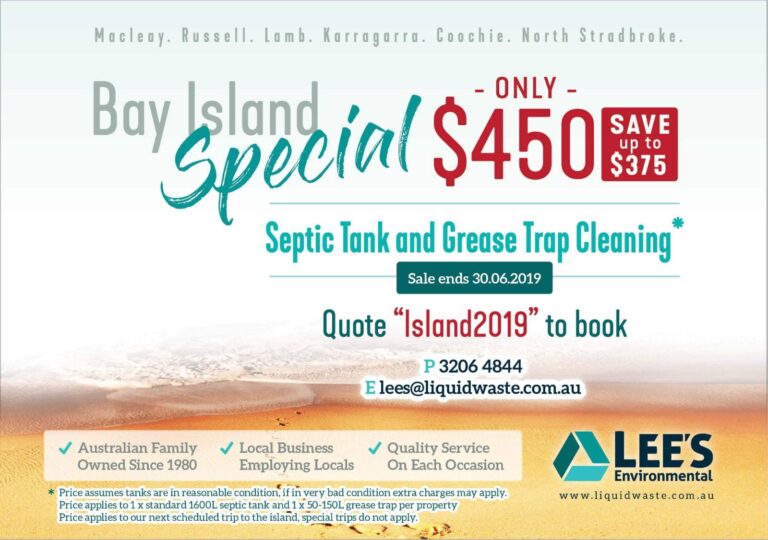

- Grease trap servicing and septic pumping.

- Industrial and civil services: non-destructive digging (NDD), high-pressure clean & capture, tank and vessel cleaning.

- Interceptor and wash bay maintenance.

- Laboratory chemical collections and small-volume hazardous liquids.

- 24/7 emergency spill response.

Coverage and response times

For multi-site operations or regional assets, network coverage matters.

- Ask for depot locations and standard response windows by region.

- Confirm after-hours support, weekend availability and public holiday arrangements.

- Define escalation paths for urgent collections or compliance risks.

Sustainability and environmental outcomes

Choose a partner that reduces waste to landfill and emissions — and documents it.

- Resource recovery rates and recycling pathways.

- Options to consolidate collections and cut truck kilometres.

- Support for ESG reporting: emissions factors, diversion metrics and continuous improvement plans.

Costs, quotes and value

Transparent pricing protects your budget and avoids surprises.

Key cost drivers

- Waste type and hazard profile.

- Volume, frequency and access constraints.

- Treatment method, disposal fees and regulatory charges.

- Out-of-hours work, stand-by time and additional labour (e.g., confined space).

What good quotes include

- Unit rates by waste stream and volume (e.g., per 1,000 litres or per tonne).

- All surcharges disclosed: levies, manifesting, tracking, disposal fees.

- Service windows, response times and any minimum charges.

Contracts and SLAs

- Defined KPIs for safety, timeliness, documentation accuracy and spill readiness.

- Annual review points to optimise routes and cost.

- Clear variation process for new waste streams or projects.

Proof points: how providers demonstrate reliability

- Relevant certifications: ISO 9001 (quality), ISO 14001 (environment), ISO 45001 (safety).

- Case studies showing risk reduction, cost control and compliance outcomes.

- Site induction readiness and alignment with your contractor management systems.

- References from similar industries and facility types.

Your vendor shortlist: questions to ask

- Which EPA licences cover our waste streams and regions?

- What are our treatment pathways and recycling options?

- How do you track waste and provide chain-of-custody reports?

- What’s your standard response time and 24/7 escalation process?

- How do you manage confined space, hot work and high-risk tasks?

- What drives our costs and how can we reduce them safely?

- Can you support a multi-site rollout with consistent documentation?

When to call a specialist immediately

If you have a spill, unknown liquids, or a suspected compliance breach, do not attempt to handle hazardous materials yourself. Engage emergency specialists to contain the risk and meet reporting obligations.

Why Australian organisations choose Lee’s Environmental

Lee’s Environmental is a full-service Australian provider specialising in liquid and hazardous waste, industrial and civil services, and 24/7 spill response across the eastern seaboard. We prioritise safety, compliance and practical solutions — keeping your operations running and audit-ready.

- EPA-licensed collection, transport and treatment with full chain of custody.

- Grease trap, septic, oily water and complex chemical streams managed end-to-end.

- Industrial services including non-destructive digging, tank cleaning, and high-pressure clean & capture.

- Rapid, 24/7 emergency spill response with experienced incident teams.

- Reporting that supports audits, EMS and ESG disclosures.

Conclusion

The right liquid waste management company combines licences, proven safety systems, responsive service and sustainable treatment pathways.

Use the checklists above to assess capability, verify documentation and secure a partner that protects people, assets and the environment — while keeping you compliant and cost-efficient.