High pressure water blasting, sometimes called high-pressure water jetting, is the go-to choice when people need squeaky-clean surfaces quickly and safely.

The service is surprisingly affordable, especially when you consider how many jobs one thorough blast can tackle.

One popular application is called hydroblasting. In this process, water is sprayed onto metal, concrete, or bricks to strip away grime and even small rust spots.

In some cases, cleaners like methanol or acetone are added to the mix, but most professionals agree plain water is kinder to the planet.

Because hydroblasting relies mainly on water, it skips the harsh chemicals found in many store-bought cleaners.

That protects nearby plants, fish, and workers from unwanted spills. It also means the surface does not sit under dangerous fumes that can cause breathing problems long after the job is done.

What Is High-Pressure Cleaning?

At its core, high-pressure cleaning shoots a steady curtain of water at up to 40,000 psi over walls, decks, boats, and equipment. Exactly how much water the machine uses depends on the tip size, but even powerful jets waste far less than a garden hose.

Yet the method is impressively fast. A single technician can blast an entire car park in hours instead of days. Water under such force gets into tiny cracks and around bolts, leaving surfaces truly clean instead of just rinsed.

Delicate engine parts in today’s vehicles or tiny gears in a factory machine need their own special cleaning recipes. That’s where high-pressure blasting shines: it angles and squeezes water into spots a human thumb just can’t squeeze into.

Water isn’t the only star in this show. When the target can’t get wet, like older circuit boards or sensitive sensors, shops swap in fine grit or compressed-air showers instead. The dust still flies but the part stays dry, safe, and environmentally friendly.

Even simple-looking hydro blasting tools need a trained crew standing by. Because of that, you usually call a waste-management or industrial-cleaning business with the right gear and certificates.

Hydro Blasting Benefits

At its core, hydro blasting shoots water—or a mix of water and solvent—at high-pressure across a surface. The basics may sound plain, yet the method packs a punch.

- Quick. Ask a car wash what saves it time, and the staff will mention the adjustable nozzle. That same trick works indoors: fine jets slip into seams, grooves and under bent edges faster than a rag can keep up.

- Quick and Flexible. Hydro blasting works fast, covering both small patios and large factory floors in minutes. Once the nozzle is set up, almost anyone can run the job with little training, and the gear needs only basic care.

- Cost-Effective. Because the high-pressure water blast cuts through grime so well, a single team can clean more surfaces in less time. That means contractors can book more jobs each day without raising costs, passing savings along to customers.

- Green Choice. Hydro blasters rely mostly on plain water, using few or no harsh chemicals. As a result, run-off is gentle on soil and waterways, which protects plants, animals, and neighbourhoods from typical cleaning hazards.

Environmental Awareness.

Greenhouse gases and climate change seem to touch almost every story we read today, and people in hydro-blasting firms feel the weight, too. Many promote water-only blasting because it leaves a smaller carbon footprint than chemical-heavy methods.

Water Blasting Process

Water blasting sounds easy, and in many ways it is. Still, each step can become risky if an untrained person takes charge.

While not made explicit here, surface preparation is a vital part of high pressure water blasting regardless of the water blasting equipment that might be used during the cleaning process.

Step 1: Pressure Generation

The very first job is to build pressure inside the machine. Because every model is different, the correct level will also change. Most manufacturers recommend a range between 700 and 1,700 bar.

During the entire cleaning job, an operator must keep one eye on the pressure gauges. Going above the safe zone can damage equipment and hurt people nearby.

Step 2: Water Filtration and Treatment

For high-pressure work, only clean, treated water should enter the tank. Dust, rust, or other particles can quickly lower the system’s efficiency.

People also need to remember that a washer once mixed with chemical soap should not simply switch to pure water.

Step 3: Nozzle Selection and Configuration

Choosing the right nozzle is also important. Each tip creates a different spray pattern, so operators must match the job at hand. Whether removing paint, cleaning steel, or blasting away grime, the correct nozzle saves time and reduces wear on the machine.

Step 4: Fine-Tune Pressure and Get to Work

Once hoses, nozzles, and jets are locked in, a trained crew runs a quick checklist of seals, gauges, and valves. Only then is the water dialed up to the pressure set on the work order. The nozzle angle, spray-width, and flow are held steady while the team walks each surface, looking for chatter that tells them if pressure is too high or too low, and watches for overspray that might damage flowers or fragile siding.

Because they do this every day, the crew notices little things the average homeowner might miss: paint flecks starting to lift, caulk pulling loose, or unseen grime hiding in shadowed corners. Their hands stay on the trigger, but their eyes double as gauges so the cleaning plays out smoothly.

Step 5: Sweep Up, Filter, and Recycle

Washing a building is more than blasting away stains; a good crew leaves the yard cleaner than they found it.

After every wall, sidewalk, and roof gets its turn under the wand, workers move in with vacuum shrouds and soft brooms to sweep up loose dirt, sand, and chemicals the rinse cycle has collected. That haul goes straight into a bulk container, preventing any stray grit from sliding into storm drains or flower beds.

Meanwhile, high-end pressure trucks are equipped with filtration pods that strain out silt, oil, and algae, so clear, recycled water can be pumped back into the skids and redeployed for final rinses. The two-step clean-up cuts freshwater use by as much as sixty percent and keeps neighbourhoods tidy while the job site stays busy.

Why Hire a Professional High Pressure Water Jetting Team

Trying to tackle big hydroblasting projects alone rarely pays off, so it’s smart to call a local pressure-cleaning firm before ladder, truck, or trailer buys turn into garage art.

Contract pros come armed not only with beastly belt-line pumps, turbo nozzles, and carbon-filter hoses, but also with sit-on-swing insurance, wastewater permits, and the kind of moxie born from blasting bridge decks, factory floors, and hospital courtyards.

As a bonus, team leads walk roofs, fences, decks, driveways, and aluminium carports first, then sketch the exact service recipe needed – pure-water flat cleaning for engraved pavers, low-pressure-surface-cleaning for cedar siding, or foam de-greasing on vintage cars – so edgy surfaces look new minus scalped wood or caked sealant.

Residential Pressure Washing

Homeowners often call a pressure-washing crew to spruce up the driveway, patio, or siding. The jet of water lifts grime faster than scrubbing by hand, yet it is gentle enough to leave surfaces intact. For the same reason, people use the service to clear gutters and drainpipes.

Industrial Cleaning

The industrial-cleaning market dwarfs many other waste-management niches. Assembly lines, warehouses, and plants often house aluminium and other metals that lose performance when coated in dust, grease, or chemical residue. Trained technicians show up with heavy-duty gear and high-pressure jets that reach into tight machinery cracks.

Green Cleaning Approaches

One of pressure washing’s biggest selling points is its light footprint on the planet. Because crews rely mostly on water—and only a pinch of soap if needed—chemical runoff is rarely a concern.

The technique also tackles ground-level spills with little risk of spreading contaminants. In fact, some operators use specially fitted guns that break up compacted gravel without causing harm.

Choosing the Right Pressure Cleaning Services

A lot of waste management businesses provide pressure washing in one way or another. There are several reasons why hydro blasting is a successful cleaning method. Concrete, steel, aluminum, and other materials can all be cleaned by it.

The process is relatively simple and cost-efficient. However, its advisable to hire an expert team within the industrial cleaning industry.

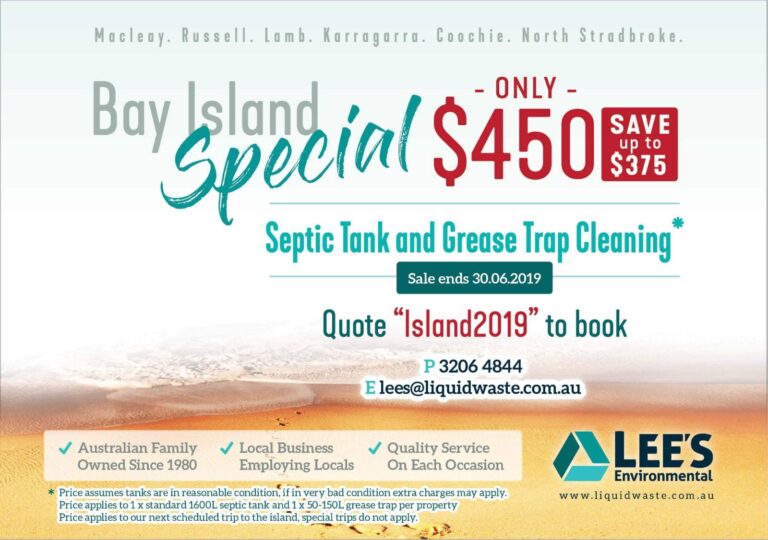

So, whether running manufacturing plant facilities, a concrete demolition team, or just need some high pressure water, be sure to call an expert team like us at Lee’s Environmental.