Liquid waste occupies a distinctive position in Australia’s modern effort to build more sustainable, eco-friendly disposal practices. While certain liquid wastes can break down naturally over time, many pose significant environmental threats.

The fluid nature of these materials does not mean they should be discharged carelessly into waterways or soil systems. Proper management becomes essential. Like other waste categories, liquid waste requires comprehensive management systems that protect both public health and environmental integrity.

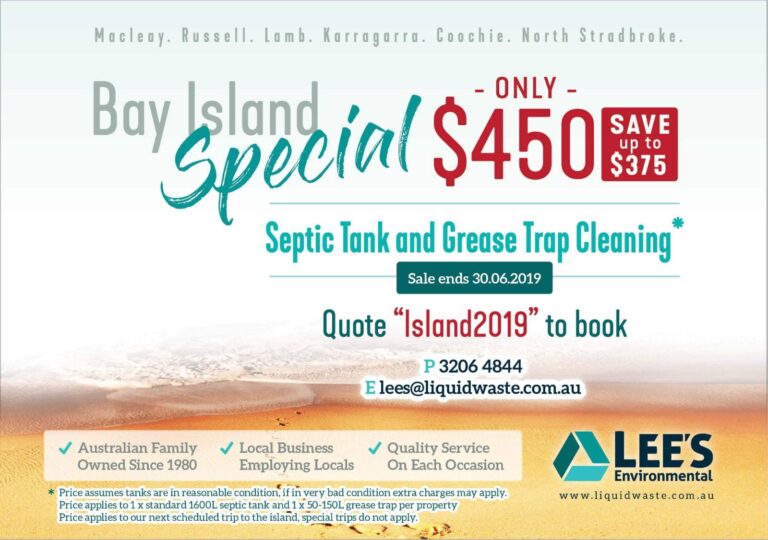

This blog explores the unique challenges of liquid waste and examines how effective disposal practices contribute to Australia’s sustainable future objectives. Given our Lee’s Environmental experienced team, we are capable of providing insights on grease trap waste, septic waste, liquid industrial waste, and general liquid waste removal.

Understanding Liquid waste

Liquid waste encompasses all discarded fluids that cannot safely enter standard sewage treatment systems without specialised processing. This means that the liquid waste industry is quite big and more than just septic tank pump outs.

Industrial solvents serve as prime examples. They perform essential functions during manufacturing processes, but spent chemicals become environmental hazards requiring careful handling. Many facilities generate substantial volumes daily through routine operations.

Similarly, the apparent harmlessness of certain liquids can prove deceptive. Used cooking oil seems benign enough, yet improper disposal creates significant infrastructure problems. Most municipal authorities spend considerable resources removing blockages caused by grease accumulation in sewer systems.

Historical evidence shows that contaminated water sources have consistently threatened public health. Early sanitation systems were developed precisely because communities recognised the dangers of mixing clean water with liquid contaminants.

What is Liquid Waste?

Liquid waste refers to discarded fluids requiring specialised disposal methods due to their chemical composition or potential environmental impact.

Common examples include pharmaceutical waste, paint residues, grease trap waste, and industrial cleaning solutions.

Determining hazard levels presents ongoing challenges for waste management professionals.

Modern industrial processes create complex chemical mixtures that weren’t encountered decades ago. Traditional disposal methods weren’t designed to handle synthetic compounds and pharmaceutical residues. You need professional assessment services to ensure compliance with current environmental regulations.

The Importance of Liquid Waste

Most developed societies recognise that liquid contaminants must be isolated from clean water supplies. Failure to maintain this separation results in widespread environmental contamination and public health risks.

Traditional disposal approaches relied heavily on dilution and discharge into water bodies. This model created long-term environmental problems as pollutants accumulated in marine ecosystems and groundwater systems.

Effective liquid waste management has become essential for protecting Australia’s water resources. Proper treatment methods allow industries to operate while maintaining environmental responsibility.

Waste Management Hierarchy

The waste management hierarchy guides current practices throughout Australia’s waste industry. Its fundamental objective involves promoting more efficient and sustainable disposal approaches.

Discharging liquid waste directly into stormwater systems or natural waterways no longer meets acceptable environmental standards.

The hierarchy operates as a six-tier system. Prevention occupies the top position as the most desirable approach, while disposal sits at the bottom as the option of last resort.

Waste Prevention

Prevention strategies focus on eliminating liquid waste generation during initial production stages. This approach addresses environmental concerns at their source rather than managing consequences after contamination occurs.

Waste Reduction

Waste reduction builds upon prevention principles by minimising liquid waste volumes throughout industrial processes. Manufacturing facilities achieve this through improved efficiency measures and alternative chemical systems. Successful reduction programs lower treatment costs while reducing strain on municipal water treatment infrastructure.

Waste Reusing

Reuse techniques occupy the middle tier of the hierarchy. These approaches assume that production optimisation has already been implemented to reasonable levels. Reuse strategies identify opportunities for treated liquids to serve alternative purposes instead of requiring immediate disposal.

Waste Recycling

Recycling represents one of the most established liquid waste management approaches, involving treatment processes that restore contaminated fluids for appropriate reuse applications. Advanced filtration and chemical treatment enable recovery of valuable materials from waste streams. Innovation drives program development. You can benefit from recycling services that reduce environmental impact while recovering operational costs. Additionally, liquid waste recycling supports job creation and circular economy development.

Waste Recovery

Recovery operations focus on extracting valuable components from liquid waste before final treatment processes begin. This approach proves particularly effective in industrial settings where expensive chemicals or rare materials can be recovered for resale.

Waste Disposal

Disposal methods are widely recognised throughout the waste management industry, yet they represent the least preferred option within the hierarchy. Disposal should function as the final solution because discharged liquid waste provides no further value to industrial or environmental systems.

Liquid Waste Management

Liquid waste management constitutes an essential component of sustainable industrial practices, focusing on proper treatment and disposal of contaminated fluids including process waters, chemical solutions, and cleaning agents. Effective management significantly reduces environmental contamination while protecting groundwater resources and enabling material recovery.

The Waste Hierarchy of Liquid Waste

Physical-chemical treatment processes form the foundation of liquid waste management. These systems employ separation technologies and neutralisation techniques to remove contaminants, producing treated effluent suitable for discharge or industrial reuse.

You can access comprehensive liquid waste services through established waste management providers who understand regulatory requirements and treatment technologies. These programs support industrial clients while ensuring environmental compliance.

Biological treatment offers another proven approach, utilising controlled microbial processes to break down organic pollutants in engineered systems. This method produces clean water and recoverable biomass while contributing to resource recovery objectives and supporting circular economy principles throughout Australian industrial sectors.

Hire an Experienced Team

The Lee’s Environmental team is a leading liquid waste removal and management team across Australia. We’re capable of handling grease trap waste, liquid waste removal, wash water services, septic tanks and holding tanks cleaning, as well as a variety of other services.